Polyvinyl chloride (PVC) is a kind of plastic products synthesized by 43% oil and 57% salt, after adding the right amount of plasticizer, can be made into a variety of hard, soft and transparent products, its mechanical properties, excellent electrical properties, acid and alkali resistance, chemical stability is also better, So why should PVC materials with better performance be added to the yellow transparent agent RQT-TS?

We all know that the processing stability of PVC is poor, the melting process is as high as 160℃, and PVC when the temperature reaches 120℃-140℃ decomposition, so PVC resin through modification to achieve melt plasticizing method to process production. On the other hand, HCL (hydrogen chloride) gas is easy to be released when the temperature reaches the decomposition temperature in the process of processing and polymerization. If its generation is not inhibited, the decomposition will be further intensified, and The Ali resonance will be generated, forming conjugated double bonds. When the number reaches more than 7 conjugated double bonds, yellow light will appear, resulting in the phenomenon of yellowing. The product produced in this situation will greatly affect the appearance of the product, and endanger the sales of the product and some influential losses, or even worse, the survival of the factory.

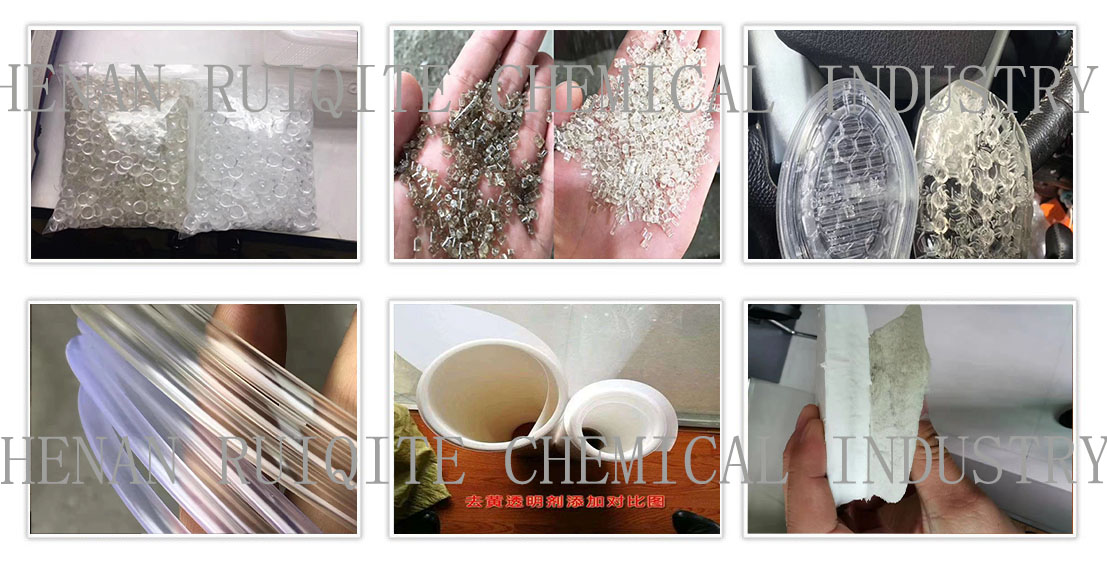

Many manufacturers and engineers try to avoid this by adding stabilizers, such as: Base class heat stabilizer (toxic), fatty acid organic tin heat stabilizer, heat stabilizer, etc., but it is not enough to add these, because different stabilizers is has its own advantages and disadvantages, so RQTchem company has developed for this problem to the company, RQT - TS, can suppress the dehydrochlorination on the basis of stabilizing agent, And to increase the transparency of the yellow effect and the late anti-yellow effect is very good. There are also manufacturers of stabilizers in the production of stabilizers when adding RQT-TS, to achieve further yellow increase transparency effect.

I have also encountered a lot of optical brightener to achieve yellow whitening manufacturers will ask, and they are currently using optical brightener what is the difference, here to distinguish according to the source of plastic yellow answer.

1.brand new material

PVC new material in the process of processing due to the processing temperature problem, thermal oxidation, accelerate the plastic oxidation yellow.

2.recycled material

Due to the use of PVC products in the process of ultraviolet radiation from the sun and air oxidation yellowing.

Combined with the above mentioned situation, the new material added to the RQT-TS, is to inhibit the emergence of yellow, and the addition of optical brightener is after the emergence of yellow, using the optical principle of optical brightener to remove yellow. To RQT-TS is added in the recycled material, suppress yellow further deepened, the addition of optical brightener is to use the same principle to whitening, so recommend to RQT-TS is added in the new material (Color matching and toning with optical brightener), Recycled PVC plastic add RQT-TS and optical brightener used together, inhibit the occurrence of yellow, first add whiteness, The effect is immediate.

Contact:Ms Yang

phone:+8618217621160

email:rqtchemical@outlook.com

name:Henan Ruiqite Chemical Industry Co., Ltd

address:F7, Hanghai International, Zhengzhou, Henan, China